It’s just over a year now since our IVT Greenline HT+ E11 11kW ground source heat pump (GSHP) was installed so I thought it would be the perfect time to reflect on our experiences of owning and running a system like this, and also importantly to do some quick analysis on how much electricity we’ve used over that period compared with previous years.

If you’re interested in previous posts relating to the heat pump, take a look at these…

A bit of background…

First, though, it’s worth a re-cap on why we decided to install a ground source heat pump in the first place. During the latter part of 2011 we extended our house considerably by converting an adjoining timber-framed thatched barn into additional living space and creating an enlarged entrance hall, a new open plan living and dining space, large kitchen and utility room. Our existing central heating and hot water system was an electrically heated wet system with radiators designed to work with low-rate electricity tariffs. Although electrically powered (which sounds frighteningly expensive!), this had worked reasonably well and efficiently over the previous 12 years since installation but it was nearing end-of-life, the manufacturer had gone out of business and it was simply not big enough to satisfy the increased demands of the enlarged property. So it had to be replaced with a new system.

After looking at all the options available to us, particularly as we are off the gas grid, and comparing various traditional technologies with newer ones, a ground source heat pump emerged as the ideal choice for us.

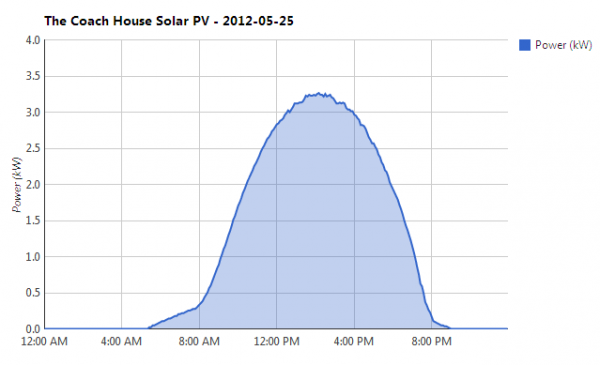

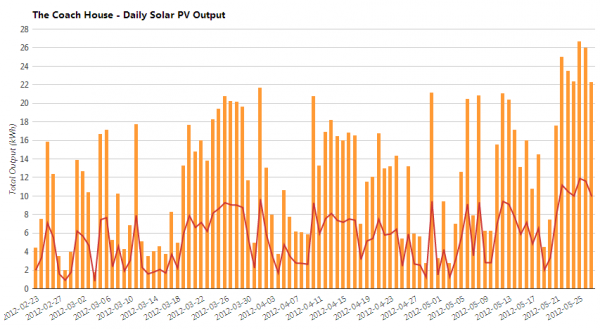

At the time we decided on a GSHP we also planned to add a solar thermal installation to supplement the hot water. As it eventually turned out, we didn’t install solar thermal and instead opted for a 4kW (peak) solar PV array which, we were told, would be a very good companion to the heat pump.

Installation and commissioning

Our GSHP system was supplied by ICE Energy, probably the UK’s biggest and most experienced supplier of GSHPs. It was important to me that we chose a company with a lot of experience given the general lack of knowledge and even awareness of this technology, and we definitely got that with ICE Energy. Their sales, engineering and technical support staff were very knowledgeable, efficient and professional at all times so I would highly recommend them to anyone else looking for a heat pump.

The installation of the heat pump, cylinder and associated plumbing was pretty straightforward for the plumber working on our barn conversion, even though he had never installed one of these before. The work associated with the installation of the ground collector pipework loops was a lot more than I had originally imagined, with some 300 tonnes of soil being moved during the course of the work: digging the three trenches, 50m long x 1m wide x 1m deep, laying 200m of coiled collector pipe “slinkies” in each trench, creating a concrete inspection chamber to house the pipework manifolds, filling the trenches back in and making good the paddock again. Having said that, it was all completed within about 4 days and even though my paddock looked like a barren wasteland for a few weeks, it didn’t take long for the re-seeded grass to grow back and look as good as it had previously.

The commissioning of the system, which included checking the basic installation, filling the collector ground loop with the heat transfer fluid and powering on the system for the first time was carried out by an ICE Energy engineer. He also talked through the basic operation of the system, how to tweak the controls and what maintenance tasks needed to be performed. There was a lot of information to take in but I also had the full manual which I read several times to make sure I absorbed the important detail.

The early days

Initial impressions of the system were very favourable. It was very quiet in operation, which was an important factor given that it is housed in specially made oak framed cupboards in our entrance hall, immediately adjacent to our main living area.

The first few months involved a lot of tweaking of the system settings in order to find an acceptable level of comfort while still trying to keep it running as economically as possible. The primary settings of the heat pump include a heat “curve” which dictates how much heat the heat pump should generate given the current outdoor temperature and the temperature of the water returning from the underfloor/radiators. The steeper the curve, the more heat it will generate at lower temperatures. There is also a “fine tune” setting which raises or lowers the heat curve (not adjusting the slope of the curve) to increase or decrease the target temperature. One other setting I tweaked was that of the domestic hot water temperature, which was initially set to 49°C. I lowered this to 47°C which was still perfectly acceptable for hot water but would squeeze a little bit more efficiency out of the system by not being required to maintain quite as high a temperature.

The installation has been problem free apart from one occasion during the first couple of weeks after installation where our new underfloor heating wasn’t reaching the desired temperature, and this turned out to be because the pressure in the unvented system had dropped. Once this was corrected we had no further problems like that.

It’s fair to say that the house, particularly in the old part with traditional radiators, was cooler than it had been previously during this initial running-in period but we eventually found the settings that worked for us under all conditions and we’ve not changed them since. In fact, that is one of the selling points of a system like this – once it is set up, you shouldn’t ever need to touch it again!

Maintenance

There is virtually no maintenance to be carried out on the GSHP and I believe this is true for the whole life of the system. You do have to check a couple of particle strainer filters a couple of times a year, one external to the heat pump unit on the ground loop circuit, and one internal to the unit. This is a straightforward task and should only take around 30 mins at most to complete.

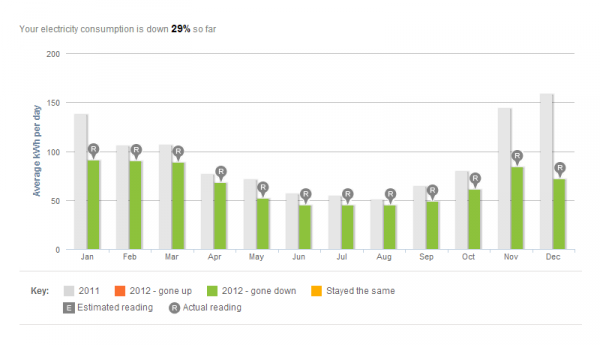

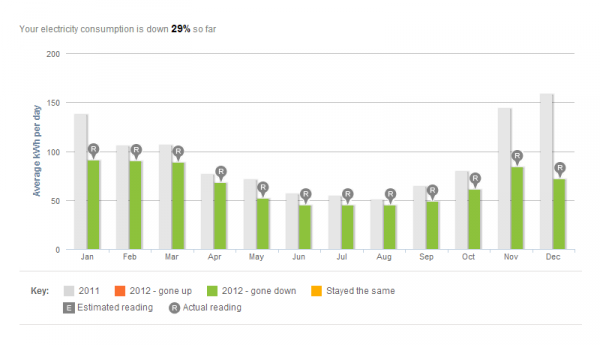

Electricity consumption

So, we finally get onto our electricity consumption over the last year. Bearing in mind the house is now almost twice as big as it was previously with a larger space to heat and more appliances and lighting, I’m very happy to report that our electricity consumption has actually gone down over the last year by around 30%! I’ve got to say I am very pleasantly surprised by this and I had feared quite a few times that we would be using more electricity.

Our solar PV system will have had some impact on these figures due to the fact we will have used our own generated electricity some of the time rather than having to import it. But this is probably not a significant factor as the times when we were generating the most electricity were a few hours during sunny Spring and Summer days when the heat pump wasn’t on much. Looking at seasonable usage, I suspect the savings are largely down to the efficiency of the GSHP when compared with our previous system. I haven’t had chance to calculate the coefficient of performance (CoP) for our system yet but this is something I would like to do in the future.

Don’t get me wrong – we still use a lot of electricity, much more than a lot of households use I would imagine – but the important and re-assuring thing is that we are now using considerably less than we did before. And given that our only fuel is electricity, this bodes well for the future.

Savings and subsidies

Savings and subsidies

Finally, I just wanted to say a little about the financial aspects of this system. In total, it probably cost us around £15K for the installation of the GSHP, which is quite a sizable up front investment, however this was offset slightly by a £1,250 installation grant under the Renewable Heat Premium Payment (RHPP) scheme operated by the UK Government. In addition to this, if all goes to plan, the new Renewable Heat Incentive (RHI) scheme should start in Summer 2013 which will provide an annual payment towards the cost of the installation, similar to the Feed-in-Tariff (FiT) scheme for Solar PV installations, over a proposed 7 year period (compared with the 20+ years for solar). This would more than cover the cost of installation of the GSHP system, and when combined with the solar FiT payments we are already receiving, will cover the cost of all of our energy usage over the next few years.